Industrial Insulation Resource Library

The Source is where we house the latest Insulation Intel on industry trends, insights, and continuing education opportunities. This is a resource built specifically to aid you in your professional development. Explore our webinars, compare specs, and follow our blog all right here at The Source.

Visit The Source for:

Project Profiles and Case Studies

CUI Protection at a Refinery

The service crew at a Washington state location put Cross-Flo®jacketing to use on a maintenance project, after first testing theproduct themselves. They’re now hopeful it can be used regularly

Berne Processing Complex

The first of three plants for the new $150 million BlueRacer Midstream LLC gas processing facility in Lewisville, Ohio called for high-temperature insulation solutions that would meet the project specifications and aggressive timeframe for delivery.

Newark Energy Center

The construction of the Newark Energy Center gas-fired powerplant in Newark, New Jersey called for the latest GE gas turbinetechnology to supply electricity to more than 700,000 homes.

Resource Libraries

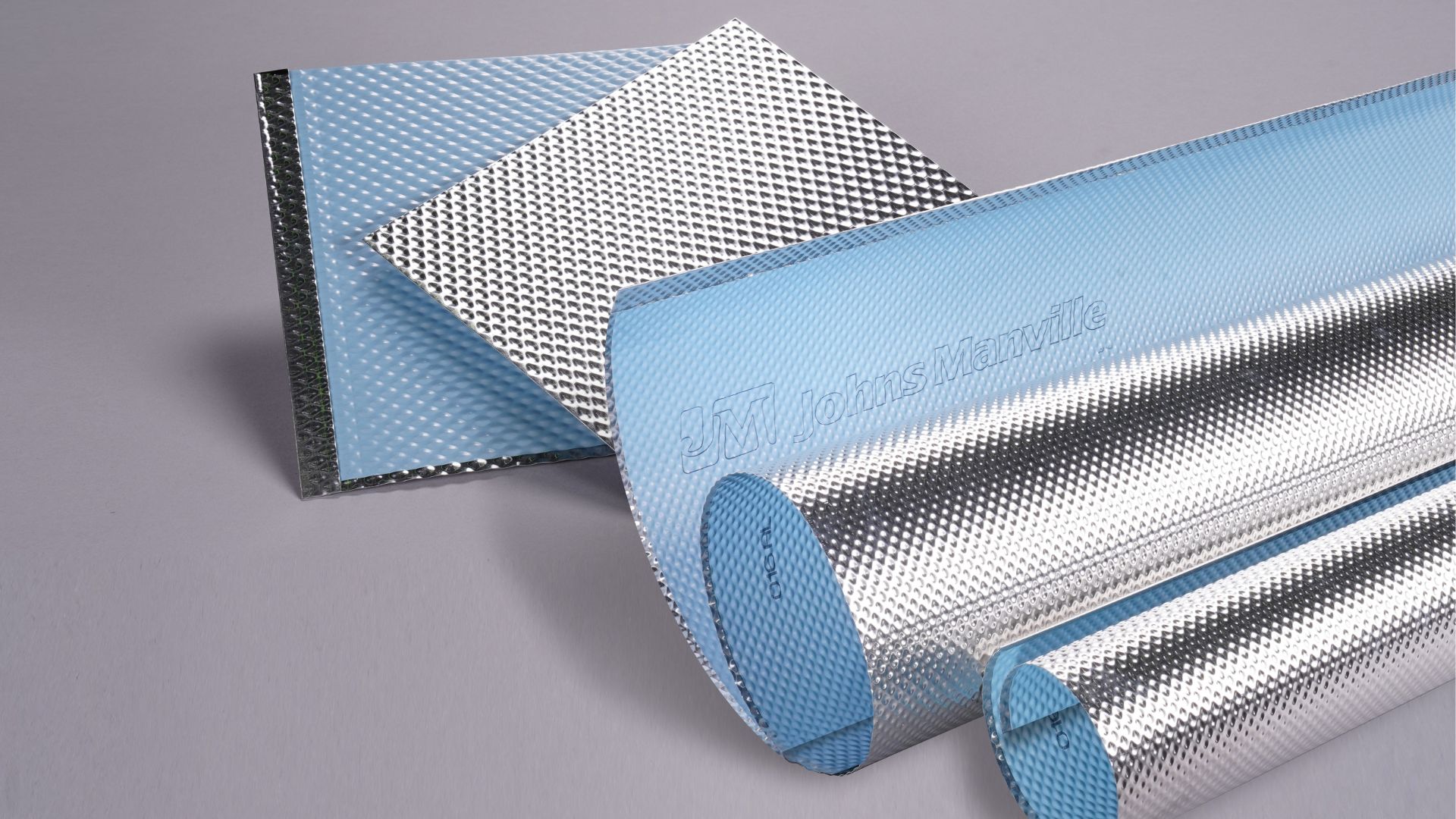

Cross-Flo® Jacketing

Water isn’t welcome inside an insulation system, so get it out – and fast – with the help of Johns Manville’s Cross-Flo Jacketing. This new product is perfect for industrial and mechanical insulation systems, helping to expel unwanted water.

Corrosion Under Insulation (CUI)

Thermal insulation is an integral part of the industrial complex. However, even the best designed and installed systems sometimes become compromised, resulting in the presence of water at the pipe surface and the potential for Corrosion under Insulation (CUI). Learn more about CUI and how JM provides the solution.

Insulation Solutions for Cryogenic and LNG Systems

Cryogenic and below-ambient pipe and tank temperatures can drop to -297°F, making a well-designed insulation system critical to ensure safe and efficient operations in an Liquefied Natural Gas (LNG) facility. At Johns Manville, we’re here to assist you with all the details you need to properly design, specify and install your cryogenic and LNG application.

Calcium Silicate Pipe and Board Insulation

Did you know that in the last 30 years, Johns Manville's Thermo-1200® calcium silicate has added corrosion inhibitors, become water-resistant, and is now offered in a curved segment configuration for large diameter (30” – 126”) equipment? Each of these changes has redefined the toughness of calcium silicate insulation and should also influence specification and installation decisions.

Our Industrial Insulation blog is the go-to source of news and information for installers, contractors, designers and distributors of industrial insulation.

Read More

Industrial Insulation Intel Blog

Cross-Flo: A Premium Metal Jacketing for All Industrial Applications

Industrial Insulation vs. Water– New Tools for an Old Battle

Why PIR Insulation is Tops for LNG Pipe

Johns Manville—Our Record Supports Our Commitment to Sustainability