Resources

Products

Single Ply Commercial Roofing

Bituminous Commercial Roofing

Liquid Applied Roofing Systems

Johns Manville’s liquid-applied systems provide a seamless waterproof membrane that is easily applied and conforms to any penetration shape. This is ideal when faced with a confined urban space, numerous roof penetrations or restricted use of hot asphalt or heat welding.

For roofs where standing water is a problem, our SeamFree™ Liquid Membrane System forms an exceptional bond, creates an elastomeric, highly protective surface and delivers exceptional waterproofing performance. The surface can be covered with reflective coatings, a cap sheet for a cool roof option or granules for an aesthetically pleasing surface.

Liquid Applied Commercial Roofing Systems

1-Part PermaFlash

Use: 1-Part Permaflash is a unique, one-component, elastomeric, liquid applied flashing material, consisting of an asphalt/polyurethane resin. It is formulated for use with Johns Manville (JM) modbit membrane products.

Type: One-part, elastomeric, liquid-applied flashing material.

Color: Brown

Features: Cures to a durable, elastomeric film and forms exceptional bonds between the modified bitumen and a variety of penetrating materials. Single component solution with no mixing required that conforms easily to various geometries or irregular shapes. UV stable, high solids (80%), low odor.

JM PMMA All Purpose Primer

Use: JM PMMA Primer All-Purpose serves as a primer for the JM PMMA system. Combined with JM PMMA Catalyst, it forms a flexible combination primer for membrane, cement board, concrete, masonry, wood, and other substrates (as recommended). JM PMMA Primer All-Purpose promotes adhesion and reduces staining on applications that contain residual or existing asphalt systems.

Type: Elastomeric, liquid-applied membrane primary layer.

Color: Translucent, Cloudy White

Features: Promotes adhesion on concrete, masonry, wood, asphalt and various surfaces. Suitable for ponding water areas. UV stable, high solids, VOC compliant.

Installation Videos

JM PMMA CATALYST

Use: For use with JM BUR and SBS membrane products. JM PMMA Catalyst is a reactive agent used to initiate curing of JM PMMA liquid resins and primer.

Type: Catalyst for two-part, elastomeric, liquid-applied PMMA systems.

Color: White Powder

Installation Videos

JM PMMA Cleaner

Use: JM PMMA Cleaner is used to clean and reactivate the transition area between existing, cured in-place JM PMMA membranes and primers and new tie-ins, repairs and staged coats of resin. This product may also be used as solvent for cleaning metal and plastic surfaces prior to resin application as well as tools and equipment used with the application of the JM PMMA system.

Type: Aromatic blended solvent

Color: Un-Pigmented

Features: Prepares fully cured and existing JM PMMA membrane and primers for a new application of fresh resin.

INSTALLATION VIDEOS

JM PMMA Detailer

Use: For use with JM BUR, SBS and JM PMMA membrane systems. JM PMMA Detailer combined with JM PMMA Catalyst to form a rapid-curing, flexible polymethyl-methacrylate (PMMA) resin containing chopped fiber reinforcement. Used in areas where fabric reinforced flashings would be difficult to install. Do not install in areas where differential movement is expected.

Type: One part of a two-part, elastomeric, liquid-applied flashing material.

Color: Light Grey

Features: Can be used to flash or repair small areas that cannot be reinforced with fabric. UV stable, high solids, VOC compliant.

Installation Videos

JM PMMA Field Resin

Use: JM PMMA Field Resin is part of a two-component, fastcuring, polymethyl-methacrylate (PMMA) system for roofing and waterproofing application. It is combined with JM PMMA Catalyst and JM PMMA Scrim to form a monolithic reinforced membrane.

Type: One part of a two-part, elastomeric, liquid-applied membrane.

Color: White or Grey

Features: Elastomeric and monolithic. Suitable for ponding water areas. UV stable, high solids, VOC compliant. Available in Summer and Winter Grade. May be combined with JM PMMA Thixo for use on vertical flashings.

Installation Videos

JM PMMA Flashing Resin

Use: For use with JM BUR and SBS membrane products. It is combined with JM PMMA Catalyst and JM PMMA Scrim to form a monolithic, self-reinforced flashing membrane for penetrations and a variety of other details.

Type: One part of a two-part, elastomeric, liquid-applied flashing material.

Color: White or Grey

Features: Can be used to flash most penetrations, drains, and vertical surfaces. Resists virtually all factors affecting base flashing performance while providing superior flexibility and durability. UV stable, high solids, VOC compliant. Available in a Summer and Winter Grade.

Installation Videos

JM PMMA Metal Primer Base and Activator

Use: The JM PMMA Metal Primer Base and Activator products serve as a primer for a JM PMMA system. They promote adhesion for various metal substrates, including drain bowls and edge metal.

Type: 100% solids, low-odor epoxy

Color: Base - Black; Activator - Clear

Features: Used to prime metal and other substrates prior to the application of a JM PMMA system.

JM PMMA Repair Paste

Use: For use with JM PMMA membrane systems. It is combined with JM PMMA Catalyst to form a rapidcuring, flexible resin for repairing substrates or covering insulation joints prior to installation of a JM PMMA system.

Type: An elastomeric liquid-applied paste.

Color: Pebble Grey

Features: Can be used to cover the joints in insulation boards to prepare them for application of a JM PMMA membrane system. Used for patching or repairs on a variety of substrates. UV stable, high solids, VOC compliant.

Installation Videos

JM PMMA Scrim

Use: JM PMMA Scrim is used in JM PMMA liquid-applied, reinforced membrane systems to improve tear strength, puncture resistance, and crack bridging capabilities. It is a non-woven, chopped strand fabric reinforcement.

Color: White

Installation Videos

JM PMMA Textured Top Coat

Use: For use with JM PMMA membrane systems in high traffic areas such as balconies or walkways. JM PMMA Textured Top Coat is combined with JM PMMA Color Pack and JM PMMA Catalyst to form a flexible resin with pre-mixed aggregate.

Type: Elastomeric, liquid-applied top coat.

Color: Not pigmented, Determined by JM PMMA Color Pack

Features:

- Added slip resistance for high traffic areas.

- UV stable, high solids, VOC compliant.

- May be combined with JM PMMA Thixo for use on vertical flashings.

Installation Videos

JM PMMA THIXO

Use: For use with JM PMMA resin systems as a thixotropic additive. It may be mixed with JM PMMA Resin or JM PMMA Top Coats to prepare the mixture to be used in slopes greater than 1.5":12", including vertical applications.

Type: One part liquid thickening agent.

Features: Prepares JM PMMA Resin and Top Coats for use on vertical surfaces. Ideal when JM PMMA Top Coat is needed for vertical surfaces or for when the JM PMMA Resin - Flashing is unavailable or not practical for use.

Intallation Videos

JM PMMA Top Coat

Use: For use with JM PMMA membrane systems. JM PMMA Top Coat is combined with JM PMMA Color Pack and JM PMMA Catalyst to form a UV stabilized, resilient finish top coat. The top coat may be smooth or applied with broadcast aggregate.

Type: Elastomeric, liquid-applied top coat.

Color: Not pigmented, Determined by JM PMMA Color Pack

Features: May be combined with JM PMMA Thixo for use on vertical flashings.

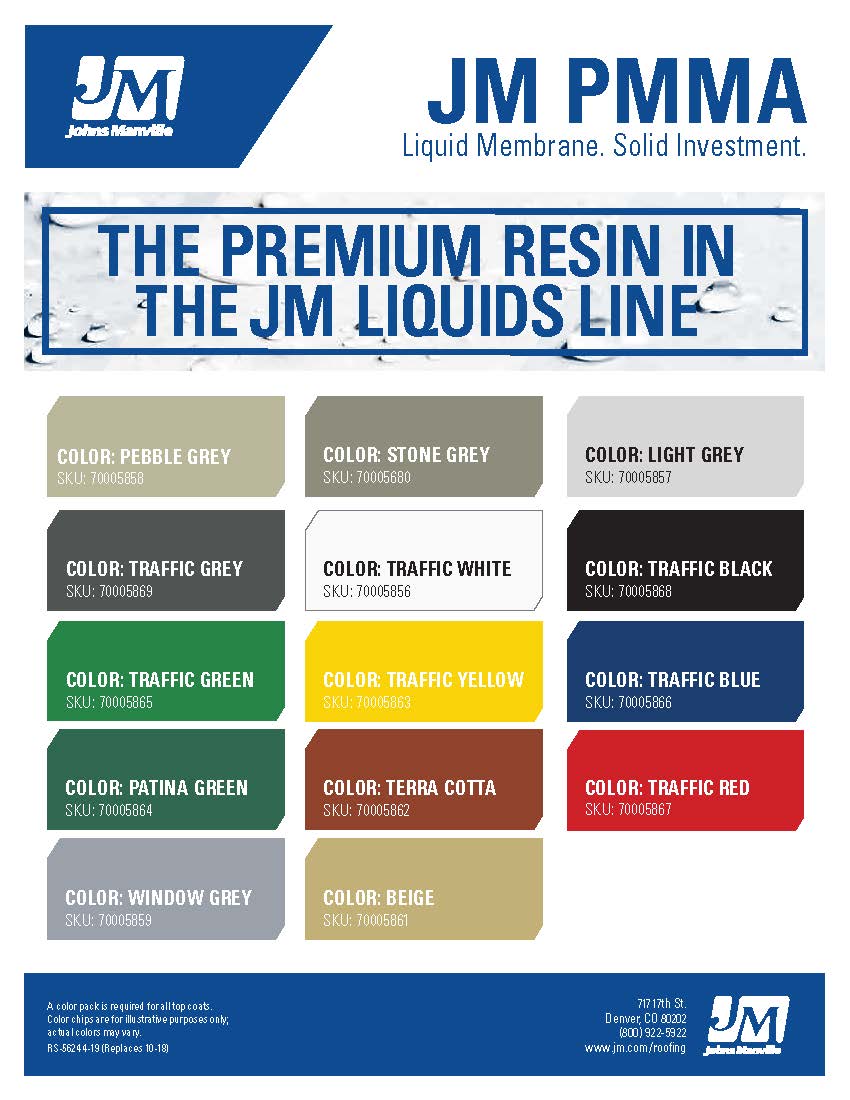

JM PMMA Top Coat Color Pack

Use: For use with JM PMMA membrane systems. JM PMMA Top Coat is combined with JM PMMA Color Pack and JM PMMA Catalyst to form a UV stabilized, resilient finish top coat. The top coat may be smooth or applied with broadcast aggregate.

Type: Elastomeric, liquid-applied top coat.

Color: Not pigmented, Determined by JM PMMA Color Pack

Features: May be combined with JM PMMA Thixo for use on vertical flashings.

JM Single Ply Membrane Primer - Low VOC

Use: To prime JM EPDM and TPO membrane surfaces for adhering EPDM or TPO peel and stick products.

Type: One-part, low VOC synthetic polymer-based membrane primer.

Color: Clear to Light Yellow

PermaFlash System

The PermaFlash System consists of PermaFlash Primer, MBR Flashing Cement, and PermaFlash Scrim. It is an integrated flashing system specifically formulated for use in bituminous systems.

Features: Can be used to flash most penetrations, drains, and vertical surfaces.

Resists virtually all factors affecting flashing performance while providing superior flexibility and durability.

High solids, low odor, VOC compliant, and UV stable.

PermaFlash Primer (Low VOC): One-Part Solvent-Based Primer that improves adhesion of MBR® Flashing Cement to nonporous substrates.

MBR Flashing Cement: Two-part, liquid-applied flashing material that cures to a durable, elastomeric film. (Please see the MBR Flashing Cement data sheet for more information.)

PermaFlash Scrim: Flexible stitchbonded polyester scrim.

Colors:

- Primer - Clear

- Liquid Base - Black

- Activator - Brown

- Scrim - White

JM SP Liquid Flashing Scrim

Use: JM SP Liquid Flashing Scrim is a polyester based, non-woven reinforcement fabric used in the JM SP Liquid Flashing system. The soft, flexible fabric is designed for use around oddly shaped, difficult penetrations and tying together different roofing substrates.

Type: Polyester fabric, scrim reinforcement layer

Color: White

Features:

Improves tear strength and puncture resistance

Easily shaped to fit even the most difficult penetrations

Helps maintain membrane and application uniformity

Available in two widths to fit your flashing requirements

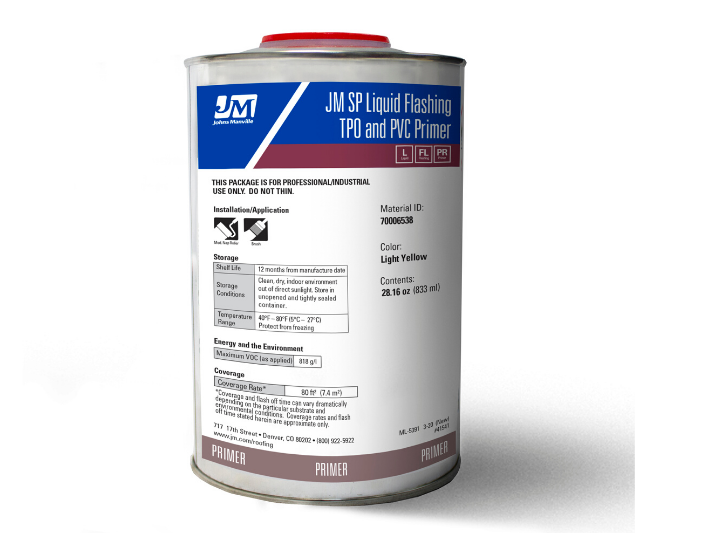

JM SP Liquid Flashing TPO and PVC Primer

Use: JM SP Liquid Flashing TPO and PVC Primer is used to prime the JM TPO and PVC (KEE and SD Plus) single ply membranes as part of the JM SP Liquid Flashing system.

Type: Single component, solvent based membrane primer

Color: Light yellow

Features:

Excellent adhesion to JM TPO and JM PVC single ply membranes.

Quick curing to speed up application time.

Single component for east 1-step application. No mixing needed, just pour and spread.

JM SP Liquid Flashing Concrete Primer

Use: JM SP Liquid Flashing Concrete Primer is used to prime properly prepared and abraded concrete and masonry substrates that comes into contact with JM single ply membranes as part of the JM SP Liquid Flashing System.

Type: 2-component, epoxy based, cold applied liquid primer

Color: Clear Part A and Yellow Part B

Features:

Excellent adhesion to a wide variety of masonry substrates

Solvent Free and Low VOC

Quick curing to support faster application times Pre-portioned and easy to use

JM SP Liquid Flashing Metal and Wood Primer

Use: JM SP Liquid Flashing Metal and Wood Primer is used to prime properly prepared and acceptable metal and wood substrates that comes into contact with JM single ply membranes as part of the JM SP Liquid Flashing system.

Type: 2-component, polyurethane based, cold applied liquid primer

Color: Tan Part A and Brown Part B

Features:

Excellent adhesion to a wide variety of metal substrates

Approved on plywood (standard and marine grade), OSB, and wood plank

Solvent Free and Low VOC

Quick curing to support faster application times

Pre-portioned and easy to use

JM SP Liquid Flashing Resin

Use: JM SP Liquid Flashing Resin, when combined with primers and scrim, creates a cold applied, reinforced liquid flashing compatible with all JM single ply membranes: TPO, PVC, & EPDM. The monolithic, self-terminating flashing membrane is ideal for tying together different roofing substrates and odd, or difficult shaped penetrations.

Type: A two-component, polyurethane based, cold applied, liquid flashing

Color: Highly reflective white

Features:

Can be used to bind multiple substrates including metal, wood, concrete and masonry

Mostly odorless, low VOC, and solvent free

Pre-portioned and easy to use

UV and color stable