A team charged with tackling a reroofing project at the Port of San Diego recently proved worth its salt, even as it dealt with the challenges posed by salt air and high-end cargo.

Chambers, Inc., dba Roof Construction, won the job to reroof National City Maritime Terminal Warehouse 24-B using a Johns Manville TPO system as the basis for design. And JM stepped in to help Sillman Architecture design a system that would meet the job’s performance requirements, which included being able to withstand the high-moisture saltwater environment.

Other challenges included being careful not to let any debris fall onto the property, which is the site of a constantly rotating inventory of high-end vehicles.

Starting with the roof tear-out, a tremendous amount of gravel was removed, along with the old built-up roof (BUR) materials and insulation down to the metal pan deck. For the reroofing, the Roof Construction crew had to build its own staircase and scaffold and use a crane to lift materials an estimated 40 feet to the job site.

Additionally, the city of San Diego required a warranty to cover the roof and the 196 4-by-8-foot domed skylights that were replaced throughout the 187,500-square-foot roof. Johns Manville and Logistics Lighting are national partners, which allowed for the skylights to roll up seamlessly under the same guarantee.

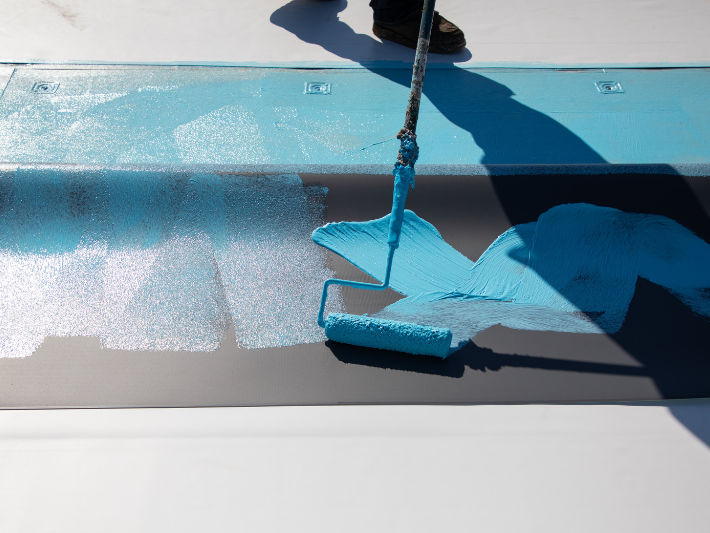

The existing roof was removed in phases to protect the interior of the building and its occupants. When installing the new roof, the crew first mechanically fastened 1 inch of JM ENRGY 3® and ProtectoR® HD to the steel deck. Next JM 60 mil TPO was fully adhered with JM Water Based Membrane Adhesive.

The environment also called for the use of stainless steel TPO clad metal for the edge detail to avoid any saltwater corrosion, instead of the more commonly used galvanized steel.

The installation happened while a parade of Mercedes, Ferraris, Audis, and other high-end vehicles were offloaded from massive freighters to the 135-acre Maritime Terminal. Each car is inspected, detailed and waxed inside the warehouse before being shipped by rail throughout the United States.

Roof Construction and JM have a history of collaboration on more than 330 projects, and like all those that came before, the team’s goal was to deliver this project on budget and on time.

JM’s dependability in delivering exactly what was needed when it was needed helped the project wrap up in February, marking the end of the seven-month job at California’s fourth largest port.

“The team at Johns Manville managed this job the same way they oversee all their jobs with us, they deliver on-time with exactly the materials we need where and when we need them. I knew going in, the job would go well, and the client would be happy with the work given our long history working together,” said Ron Chambers, Owner/President of Roof Construction.